Jerry Chilibecki

Mobiltex

Pipeline compliance requires accurate and frequent monitoring. For oil and gas companies the challenge is finding a cost-effective, reliable system and not all satellite-based monitors are created equal.

“Our objective was to create a simple, quick-to-install device that could easily integrate with the hundreds of thousands of corrosion test points already deployed on pipelines across North America. Globalstar’s STX3 modem has made that possible,” says Jerry Chilibecki, Engineering Director of Mobiltex, a leading remote-monitoring manufacturer in the cathodic protection industry.

In the past, companies installed private terrestrial radio systems at multitudes of test stations along pipelines. The sites were in distant, hostile environments with limited or no access to terrestrial communications—and no electrical power supply. Companies then transported field workers by vehicle or helicopter to transmit readings from each station.

“Our objective was to create a simple, quick-to-install device that could easily integrate with the hundreds of thousands of corrosion test points already deployed on pipelines across North America. Globalstar’s STX3 modem has made that possible.”

In the 90s, satellite technology began enabling remote automation. This transformation resulted not only in dramatic savings in time, personnel and fuel, but also accurate and repeatable results.

Mobiltex entered the market in 1991. Since then, the company has designed three generations of remote monitoring units and equipment, providing solutions to over 100 oil and gas companies across North America.

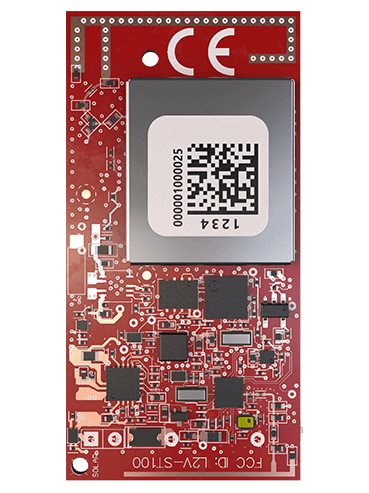

When Mobiltex began designing the CorTalk RMU1, its transformative machine-to-machine monitoring device, the three guiding principles were simplicity, reliability and adaptability. The company chose to integrate Globalstar’s STX3 Satellite Transmitter due to features of both the device itself and the company’s space segment.

“Globalstar’s Low Earth Orbit constellation provides a big advantage, both because of the stability of the network and the fact that it does not need as much RF power to communicate with the satellites,” says Chilibecki. “The result is lower demands on battery systems and overall operational efficiencies. That’s why we chose Globalstar’s STX3 modem.”

The altitude of Globalstar’s satellites produce the largest spot beams of any Low Earth Orbit operator, minimizing the number of satellites required and resulting in lower costs. The orbit, inclined at 52 degrees, provides comprehensive coverage between 70º north and south. A geostationary system, in contrast, mirrors the Earth’s orbit. In such systems, it’s impossible to determine where a device will work, but Globalstar’s rapidly orbiting satellites ensure visibility from most any part of the sky.

In addition, geostationary systems require significant RF power on the ground. The vulnerability of the large batteries and costly solar panels required further strained budgets. The STX3 provides an ideal alternative: its extreme efficiency allows RMU1 batteries to last from 5 to 10 years, depending on reporting frequency.

“Because the STX3 is so compact (it’s about the size of a quarter), and efficient with the lowest power consumption in the industry, we were able to integrate the complete antenna system, modem, battery and remote measurement elements and retrofit it into existing industry standard 3-inch diameter test stations along remote areas of pipeline,” says Chilibecki. The resulting CorTalk RMU1 is a game-changer for the industry.

As the natural resource sector increasingly turns to satellite solutions for dependable, fast connections among its growing M2M networks, Globalstar is emerging as a game-changer as well.

SmartOne Solar

SmartOne Solar SmartOne C

SmartOne C ST100

ST100 STX3

STX3 STX3 Dev Kit

STX3 Dev Kit SPOT X

SPOT X SPOT Gen4

SPOT Gen4 SPOT Trace

SPOT Trace